Warehousing and logistics centers are very important. They help move goods around the world. The logistics sector has big fire risks. This is because there are many items stored close together. There are also many different materials. Many places lose money each year because of fires.

In countries like the United States, South Africa, and Germany, warehouse fires happen regularly and sometimes cause significant financial losses. In Southeast Asia, countries such as Indonesia, Thailand, and Malaysia also face frequent warehouse fires, creating serious safety and economic challenges. The rapid growth of logistics in these regions often outpaces fire safety measures.

Even with better fire protection, costs keep going up. Fire protection failures are expensive. Warehouses need strong fire safety and preventive steps. Good fire protection is needed for every warehouse.

Key Takeaways

-

Warehouses have high fire risks. This is because flammable materials are stored close together. The layouts are also complicated. Regular risk checks are important. Workers need training to stay safe.

-

Good warehouse design helps stop fires from spreading. Wide aisles make it easier for firefighters to get in fast. Using fire-resistant materials is important. Storing things the right way helps prevent fires.

-

Smart fire detection systems like TYEE use special sensors. They send alerts right away if there is a fire. These systems help find fires early. They also lower the number of false alarms. This makes safety and response better.

-

Automatic sprinkler systems work best with fire detection. They need regular check-ups to work well. This helps put out fires quickly and safely.

-

Warehouses must follow fire safety rules. Keeping good records is important. Regular fire drills help everyone know what to do. This keeps people and property safe. It also helps meet legal standards.

Fire Safety Risks in Warehousing and Logistics

Common Hazards

Warehousing and logistics centers have big fire risks because of how they work. When items are packed close together, sprinklers may not work well. Many places keep flammable things like paper, chemicals, and oils. Old or broken electrical equipment can also cause fires. New storage technology can make new problems. Small groups of goods might block spaces needed to stop fires. Firefighters have trouble reaching goods that are packed tight. This makes putting out fires harder. Smoke can move fast and hurt electronics, HVAC systems, and stored items.

Tip: Training workers often and keeping flammable things away from heat can lower fire risks.

Reports say the United States experiences over 1,400 warehouse fires each year.These fires can hurt people, cause deaths, and destroy property. Recent fires in Detroit, Plainfield, York County, West Baltimore, and Commerce show how bad warehouse fires can be. This is true even with new fire suppression systems. Good fire safety needs strong detection, good sprinkler plans, and teamwork with local fire crews.

Risk Assessment

Managing fire risks starts with a careful fire risk check. Many places use a checklist based on fire codes. This list covers exits, fire systems, cleaning, wiring, and dangerous materials. Managers walk through the building to check if rules are followed. Some places use risk scores or models to see how they are doing and look at how people act.

A clear checklist helps manage fire risks step by step. It lets managers find problems and fix them. This way is easy and saves money for warehouses. Full checks make sure places follow fire safety laws and lower the chance of fires.

Facility Design and Fire Prevention

Facility Layout and Storage Practices

A good warehouse layout helps stop fires from spreading. Warehouses use special materials to slow down flames. Fire-resistant walls and doors keep fire in one area. Ventilation systems help control smoke and keep air clean during emergencies. Escape routes must be easy to find and use so people can get out safely.

Checking fire protection systems often makes sure they work when needed.

How things are stored is also important for fire safety. Here are some key points:

-

Aisles must be wide enough for people and emergency teams.

-

Wide aisles help firefighters move their equipment fast.

-

Racks should not be too high or block sprinklers.

-

Space between racks lets water from sprinklers reach fires.

-

Using fire-resistant racks gives extra fire protection.

-

Regular checks make sure everything follows the rules.

Automated storage systems need special fire safety steps. These include changing sprinkler systems, making sure there is enough water, and working with fire crews to make safety plans.

Electrical and Equipment Safety

Electrical systems can cause big fires in warehouses. Fire safety starts by following the newest electrical rules and using safety devices like Arc Fault Circuit Interrupters. Warehouses use sensors to find hot spots in wires. Predictive maintenance helps find problems before they start fires.

Important fire safety steps are:

-

Keep wiring diagrams current and correct.

-

Check motors and controls to make sure they are safe.

-

Look at fuses and circuit breakers for problems.

-

Put fire extinguishers for electrical fires in the right places.

-

Test and fix sprinkler systems as needed.

Training workers and having emergency plans help lower fire risks. Fire safety systems like smoke detectors, heat detectors, automatic suppression, and emergency shutdowns are very important.

Hazardous Materials Management

Storing hazardous materials needs strict fire safety steps. OSHA, NFPA, and EPA have rules for safe storage and handling. Warehouses use fire-resistant buildings, fire-rated doors, and good ventilation to handle fumes. Limits on storage keep flammable liquids from building up. Chemicals that do not mix well are kept apart by barriers or in different rooms.

|

Hazardous Material |

Common Risks |

Recommended Fire Safety Protocols |

|---|---|---|

|

Flammable Materials |

Fire hazards due to flammability |

Use fire extinguishers, smoke detectors, sprinklers, and alarms; check them often; make clear escape plans and emergency steps. |

|

Hazardous Chemicals |

Chemical exposure |

Follow storage and handling rules; train workers; keep safety sheets easy to find. |

|

General Fire Hazards |

Electrical faults, human error |

Hold fire drills; teach workers how to use fire extinguishers and leave safely; keep fire safety gear ready. |

Warehouses use extra containers, automatic fire suppression, and gas leak detectors for more safety. Workers learn about hazardous materials and what to do in emergencies. Checks by officials make sure rules are followed and fire safety stays strong.

Fire Detection and Alarm Systems

Modern warehousing and logistics centers use advanced fire detection and alarm systems. These systems help keep people, property, and business safe. Early warning is very important in these places. Warehouses have high ceilings and lots of storage. Their layouts are often complex. This makes fire detection harder. TYEE has smart solutions that help meet strict fire protection rules. These systems work well and are reliable.

TYEE Automatic Fire Alarm System

The TYEE automatic fire alarm system is key for big warehouses. It uses smart wireless sensors to find smoke, heat, and gases early. These sensors work in tough spots with high racks and open spaces. The system uses special algorithms to tell real fires from things like dust or steam. This means fewer false alarms. Staff only respond to real emergencies.

TYEE gives alerts in many ways. When a fire starts, sirens and flashing lights go off. People get warnings on their phones, by text, and by calls. This helps everyone get the message fast. The system also works with emergency lights and signs. These change in real time to guide people away from danger. TYEE uses a cloud platform for live monitoring and smart analytics. Managers can spot risks and act before fires spread.

Note: The TYEE automatic fire alarm system has helped in places like Gwadar New International Airport and Hangzhou Metro Line 3. Early detection and quick action kept people and property safe.

Fire Alarm Controllers

Fire alarm controllers are important in modern fire safety systems. TYEE controllers use addressable technology. This means they can show the exact spot of a triggered device. This is very helpful in large logistics centers. Knowing where a fire starts saves time.

Addressable controllers have many good features:

-

They give details about each sensor and alarm point.

-

They work with other fire protection systems like sprinklers and emergency lights.

-

They let people monitor and control things from one place.

These controllers help meet strict fire safety rules. They make it easier to follow new laws. They keep records and check the system in real time. Predictive maintenance and self-checks mean fewer manual inspections. The system stays reliable.

Non-addressable Fire Alarm Systems

Non-addressable fire alarm systems are good for smaller or simple warehouses. These systems split the building into zones. When an alarm goes off, staff know which zone has the problem. They do not know the exact device. This works well in easy layouts. Staff can quickly check the area.

Non-addressable systems have these features:

-

Easy to install and use.

-

They find smoke and heat well.

-

They cost less for small places.

Non-addressable systems do not show the exact spot like addressable controllers. But they still give basic fire protection. They help warehouses meet fire safety needs. They also help people leave safely in emergencies.

Why Intelligent Fire Detection Matters

Smart fire detection systems give many benefits to warehouses and logistics centers:

-

Multi-sensor detectors find smoke, heat, and gas. This lowers false alarms.

-

Advanced tech helps people respond faster and spot dangers better.

-

Predictive maintenance and remote checks keep systems working and up to code.

-

They connect with building systems to automate emergency actions like shutting down HVAC or starting suppression.

These features help warehouses keep strong fire safety. They lower business problems and help follow industry rules. By picking the right mix of automatic fire alarm systems, controllers, and non-addressable options, operators can build a strong fire safety plan for their needs.

Automatic Sprinkler Protection and Suppression

Automatic sprinkler protection is very important for warehouse fire safety. Sprinklers turn on fast when heat from a fire touches them. They work by themselves and do not need people to start them. In logistics centers, goods are stacked high and hard to reach. Automatic sprinklers can stop fires quickly and work well. Studies say these systems stop fires about 87% of the time. This is better than using manual ways. Sprinklers help keep people and goods safe. Insurance companies like places with strong fire suppression systems.

System Integration with Detection

Modern fire safety needs fire detection and suppression to work together. Warehouses use smart fire detection to find smoke, heat, or gas early. When these systems find a fire, they turn on the sprinklers right away. This helps stop fires fast, even in hard-to-reach spots. Good fire safety steps include:

-

Doing risk checks to match systems to storage.

-

Making fire suppression systems that can grow later.

-

Using ESFR sprinklers for tall storage.

-

Updating old warehouses for better fire safety.

-

Linking detection and suppression for real-time alerts.

TYEE’s fire detection and alarm systems work with automatic sprinklers. This makes a strong fire safety plan. It helps sprinklers work better and start fast when a fire is found.

Maintenance and Testing

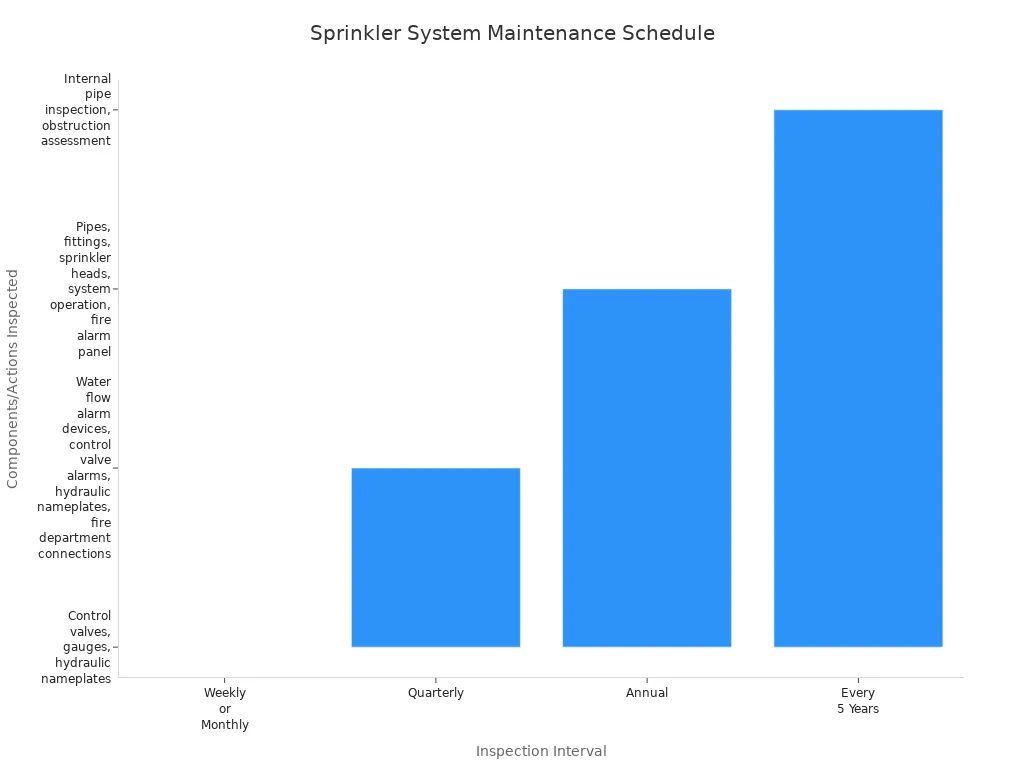

Regular checks and tests keep fire suppression systems working well. Warehouses must look at and test sprinklers, valves, and alarms often. The table below shows how often to check each part:

|

Inspection Interval |

Components/Actions Inspected or Tested |

Purpose/Notes |

|---|---|---|

|

Weekly or Monthly |

Control valves, gauges, nameplates |

Make sure everything is set right |

|

Quarterly |

Water flow alarms, valve alarms, connections |

Check alarms and make sure they work |

|

Annual |

Pipes, fittings, sprinkler heads, system operation |

Full check by experts |

|

Every 5 Years |

Internal pipe inspection, obstruction assessment |

Find hidden problems |

Yearly checks by trained workers help keep fire systems strong. Staff should learn fire safety steps and what to do in emergencies. Digital tools like QR codes help track checks and make fire safety better.

Emergency Lighting and Evacuation Solutions

TYEE Evacuation Indication System

Warehouses need clear emergency lights and signs to keep people safe. The TYEE evacuation indication system uses live fire data to help people escape. Bright LED signs and emergency lights show the way out. These lights can be seen even if there is smoke or it is dark. Managers can check each device from one place and find problems fast. The system links with fire alarms and building controls, so all warnings work together. If the power goes out, backup batteries keep the lights on. TYEE’s products work well in tough warehouse places. They are protected from dust, water, and hot or cold weather. In a real fire at a Shenzhen factory, workers followed the lit paths and got out safely.

TYEE’s moving signs help people stay calm and leave fast and safe.

Safe Egress Planning

Good emergency plans need more than just lights and signs. Warehouses plan safe exits using things like shiny tape, portable lights, and LED markers. Staff use radios and phone apps to give updates and guide people. Local emergency teams help at exits to keep everyone safe. Warehouses set up special spots for rideshare pickups and control traffic to stop jams. Planners change these steps based on how big the warehouse is, how many people are there, and things like weather or night shifts. These actions stop accidents and help people get out fast.

|

Emergency Lighting Task |

Minimum Illuminance |

Area Coverage |

Duration |

Time to Reach 50% / 100% |

|---|---|---|---|---|

|

Escape route lighting |

2 meters on the floor |

1 hour |

5s / 60s |

|

|

Corridor or direction change |

1 lux |

Within 2 meters |

1 hour |

5s / 60s |

|

Exit signs on escape route |

2 cd/m² |

Safety sign area |

1 hour |

5s / 60s |

|

Points of emphasis |

5 lux |

First aid/fire gear |

1 hour |

5s / 60s |

Human Factor: Training & Preparedness

People are very important for fire safety. Regular training teaches workers how to spot dangers and use fire extinguishers. Training shows the P.A.S.S. steps—Pull, Aim, Squeeze, Sweep—so everyone knows what to do. Workers practice sounding alarms, following escape routes, and meeting at safe spots. Fire drills help people remember what to do and feel ready. These drills help people act faster and lower risks. Training and practice make the warehouse safer for all.

Smart Fire Safety Solutions by TYEE

Integrated Monitoring

TYEE is a leader in smart fire safety for warehouses. Their system links many sensors all over the building. These sensors watch for heat, smoke, and air changes. The system uses IoT and wireless tech to join fire detection, alarms, and emergency help in one place. Staff and emergency teams get alerts right away so they can act fast.

Warehouses use 4G/5G IoT platforms to watch more areas and manage better. TYEE’s system works with building controls for full safety checks. Remote checks and repairs keep fire safety strong. Live monitoring and smart data help teams act faster and make evacuations better.

-

Fire detection, alarms, and emergency help are joined in one system

-

Staff and emergency teams get alerts right away

-

4G/5G IoT platforms help watch more places

-

System links with building controls

-

Many sensors help find fires early

-

Remote checks and repairs keep things working

-

Live monitoring helps teams act fast in emergencies

|

Technology Type |

Key Features |

Application in Logistics Centers |

|---|---|---|

|

Flame Detector Sensor |

Finds fires very fast |

Made for warehouses; works with fire alarms for full safety |

|

Gas Alarm Sensor |

Finds dangerous leaks quickly |

Stops explosions; easy to read screens and alarms; settings can be changed for safety |

TYEE’s system gives early warnings and helps staff make quick choices for fire safety.

Real-Time Alerts and Automated Response

TYEE’s smart fire safety uses real-time alerts and automatic actions to lower fire losses. The system sends messages to phones and makes calls. Managers and owners get these alerts even if they are not at work. This helps people act fast when there is a fire.

The system works with security and video checks to make emergency actions better. Early warnings and quick help lower fire damage and keep work going. These systems help follow fire rules and insurance needs, which saves money and avoids trouble.

The system protects all day and night, even when no one is there. Real-time IoT alerts use sensor data to spot fires fast. This means help comes quickly and people know what to do. Automatic actions like closing fire doors and turning off power stop fires from spreading. Fast alerts and automatic steps help teams act quickly and know what is happening. These things are very important to keep warehouses safe from fire.

TYEE’s smart fire safety helps warehouses stay safe, protect goods, and keep business running.

Compliance and Industry Standards

Regulatory Requirements

Warehousing and logistics centers must follow strict fire safety rules. These rules keep people safe and protect buildings. Every country has its own codes, but some rules are used everywhere. The National Fire Protection Association (NFPA) makes important rules in the United States. Some of these are NFPA 1 for general fire safety, NFPA 10 for extinguishers, NFPA 13 for sprinklers, NFPA 25 for checks, NFPA 30 for flammable liquids, NFPA 70 for electrical safety, NFPA 72 for alarms, and NFPA 101 for life safety. OSHA also makes sure workplaces have safe storage, clear exits, and trained workers.

Local fire departments check if warehouses follow these rules. Some rules like ISO 20710-1:2022 and ISO 45001:2018 are used in many countries. The International Building Code (IBC) and EN 13501 are used in Europe. Australia uses the National Construction Code. The United Kingdom uses the Regulatory Reform (Fire Safety) Order 2005. Canada uses the National Fire Code. These rules cover stopping fires, finding fires, putting out fires, and getting people out safely. Warehouses must follow these rules to lower fire risks and keep fire safety strong.

Tip: Checking local and world rules often helps warehouses stay safe and follow fire safety steps.

|

Standard/Code |

Region/Country |

Focus Area |

|---|---|---|

|

NFPA Codes |

United States |

Fire protection, suppression |

|

OSHA Regulations |

United States |

Workplace fire protection |

|

ISO Standards |

International |

Fire protection, safety systems |

|

EN 13501 |

Europe |

Fire classification |

|

NCC 2022 |

Australia |

Performance-based fire protection |

|

NFC 2020 |

Canada |

Prevention, life safety |

Documentation and Audit Preparedness

Warehouses need good records to show they follow fire safety rules. Managers keep up-to-date policies and SOPs for fire safety. They write down when workers train and practice fire drills. Logs for fire extinguishers, alarms, and sprinklers show that everything works.

Warehouses do regular checks inside to find problems and fix them fast. Central systems help track policy changes, audit results, and new rules. This makes fire safety part of daily work. Workers get ready for surprise checks by keeping exits clear and papers ready. When rules change, managers update training and records right away.

-

Training records show workers are ready for fire safety.

-

Logs prove fire safety equipment works.

-

Inside checks help find and fix fire safety problems.

-

Central systems track changes and audits.

-

Workers get ready for surprise checks with up-to-date records.

-

Managers update papers and training when rules change.

These steps help warehouses keep strong fire safety and always manage fire risks.

Fire safety in warehousing and logistics centers needs different plans. Operators should pick solutions that fit the building, what is stored, and local needs. Using connected fire safety systems helps people make better choices. It also helps teams work together and use data to improve how things run. Spending money early on fire safety keeps the supply chain working and helps the business stay strong. Some main benefits are:

-

Better choices about risks and how to use resources

-

Fast action from automatic sprinkler systems

-

Keeping goods safe and work going without stops

A good fire safety plan helps logistics centers grow and stay safe for the future.

FAQ

What makes TYEE fire alarm systems suitable for warehouses?

TYEE fire alarm systems have smart sensors and give quick alerts. They work well in big places with tall racks. These systems help workers find fires early and act fast. TYEE also links with other safety tools for full protection.

How often should warehouses test fire safety equipment?

Warehouses need to test fire alarms, sprinklers, and emergency lights every year. Some things, like control valves and gauges, need checks every month or week. Regular tests make sure all systems are ready for emergencies.

Can TYEE evacuation signs work during power outages?

Yes. TYEE evacuation signs have backup batteries inside. These lights stay on if the main power goes out. People can always see safe exits, even if it is smoky or dark.

Why is staff training important for warehouse fire safety?

Training helps workers spot fire dangers and use safety tools. Drills show everyone how to leave safely. Well-trained workers can act fast, lower risks, and keep people and things safe.

Do TYEE systems help meet global fire safety standards?

TYEE systems follow important rules like NFPA, ISO, and EN codes. These systems help warehouses pass checks and follow the rules.